Tailored mechanical engineering industry support solutions.

Tailored mechanical engineering industry support solutions.

Blog Article

Professional Solutions for Electric System Troubleshooting and Repair Services

Reliable troubleshooting and repair work of electric systems require a methodical technique, leveraging both progressed analysis devices and skilled knowledge. Typical issues such as circuit overloads and malfunctioning electrical wiring demand immediate interest, yet the complexities of electric systems can commonly cover the underlying troubles. Safety and security methods are extremely important, as also small oversights can bring about substantial risks. Understanding when to involve a specialist can make all the distinction in guaranteeing both safety and system stability. As we explore the important components of electric troubleshooting, the effects of disregarding these best techniques come to be progressively obvious.

Usual Electrical Troubles

While electrical systems are designed for reliability, they can often come across a variety of usual problems that might interrupt capability and safety. One common issue is circuit overload, which takes place when also numerous tools draw power from a solitary circuit, causing tripped breakers or blown integrates. technical support for electrical industry. This can not just restrain electrical efficiency but also posture a fire threat

One more frequent trouble is malfunctioning electrical wiring, often because of age, wear, or inappropriate setup. Damaged or frayed wires can result in short circuits, resulting in blackouts or electric shocks. In addition, loosened links can cause recurring power loss, creating frustrating and potentially hazardous circumstances.

Ground mistakes are an additional concern, especially in wet or damp settings where electric equipment is utilized. These mistakes can trigger severe safety dangers, necessitating immediate interest to make sure appropriate grounding and circuit defense.

Finally, flickering lights can indicate problems varying from overloaded circuits to faulty lights. Recognizing these typical electrical issues is crucial for maintaining the integrity and safety and security of electric systems, ensuring they run effectively and successfully. Resolving these issues quickly can stop more extreme problems and improve general system integrity.

Analysis Devices and Techniques

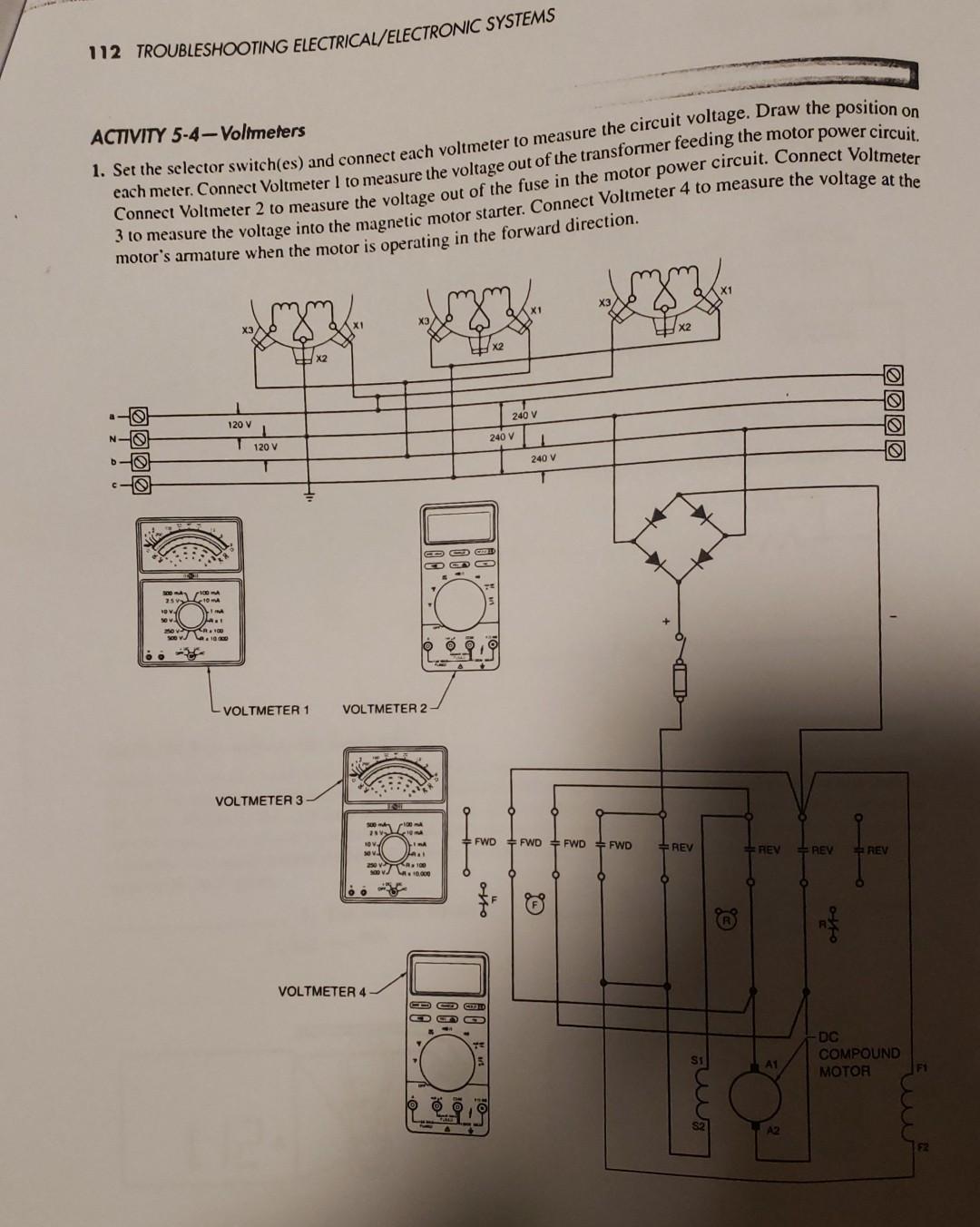

Utilizing precise diagnostic tools and techniques is important for properly determining and fixing electric system issues. Numerous instruments assist in precise assessments, ranging from simple multimeters to innovative oscilloscopes - technical support for electrical industry. Multimeters are essential for determining voltage, present, and resistance, enabling technicians to rapidly pinpoint faulty elements or links

Clamp meters are specifically beneficial for determining current without disrupting the circuit, improving safety and security throughout diagnostics. For even more complicated troubleshooting, oscilloscopes permit the visualization of electric signals gradually, providing insights right into waveform abnormalities that may suggest underlying troubles.

In addition to these tools, infrared thermography is indispensable for finding overheating elements, which can represent upcoming failings. Insulation resistance testers additionally help in recognizing endangered insulation, important for protecting against electric hazards.

Techniques such as visual inspections, connection tests, and circuit mapping are also indispensable to an efficient analysis process. By incorporating these devices and strategies, specialists can develop an extensive understanding of electric systems, ensuring exact medical diagnoses and reliable repairs. Inevitably, leveraging the ideal diagnostic resources not just improves repairing performance however also contributes to the durability and security of electrical installations.

Step-by-Step Troubleshooting Overview

Following, utilize analysis devices such as multimeters and circuit testers to look for continuity, voltage, and current flow in the circuit. Start at the power source, verifying that it is operational, then trace the circuit detailed, inspecting each part in the process. Document your findings to maintain clarity throughout the procedure.

When address you have actually determined the defective component, separate it from the circuit. Do necessary fixings or substitutes, making sure that all circuitry and links are safe and secure. After attending to the issue, reconsider the whole system to verify that it runs properly.

Safety And Security Preventative Measures Throughout Repair Work

Ensuring security during electric repair work is paramount to stop crashes and injuries. Before starting any type of job, it is important to turn off the power supply at the have a peek here breaker and validate that the circuit is de-energized using a trusted voltage tester. Personal protective devices (PPE), including shielded handwear covers and safety goggles, should be put on to mitigate the risk of electrical shock and eye injuries.

Furthermore, keeping a clutter-free work area is vital. Make sure tools remain in great problem and appropriate for the tasks handy. Making use of tools with insulated takes care of can additionally improve safety. It is additionally essential to stay clear of dealing with electrical systems in damp or wet conditions, as dampness substantially boosts the risk of electrical shock.

Secure loosened clothing and connect back lengthy hair to avoid any kind of entanglement with electrical elements. Familiarize on your own with the specific electric codes and laws relevant to your area to ensure conformity and security throughout the repair procedure.

When to Call an Expert

While safety preventative measures are vital for any type of electric repair work, there are circumstances where the intricacy or range of the job requires the know-how of an expert electrician. Homeowners need to be especially mindful when taking care of issues that include circuit breakers, electrical panels, or the major power supply. Any indicators of electrical fires, such as burned scents or flickering lights, warrant instant expert attention.

In addition, if you run into consistent tripping of circuit breakers or frequent electric surges, these may show underlying issues that need specialized analysis tools and expertise. Jobs that necessitate extensive rewiring, installment of brand-new circuits, or connections to high-voltage systems should constantly be delegated certified electrical experts, as inappropriate handling can lead to serious threats.

In addition, regulative compliance is important in electric job. Professionals are acquainted with regional codes and policies, ensuring that all fixings meet safety and security criteria.

Conclusion

Finally, efficient fixing and repair work of electric systems call for a methodical approach, leveraging innovative analysis devices and adherence to security preventative measures. By recognizing common electric problems and using an organized troubleshooting guide, lots of concerns can be settled successfully. In situations of intricacy or click for more safety and security problems, seeking advice from a qualified electrician stays crucial. This ensures not only the stability of the electric system however additionally the security of individuals and residential or commercial property entailed.

Report this page